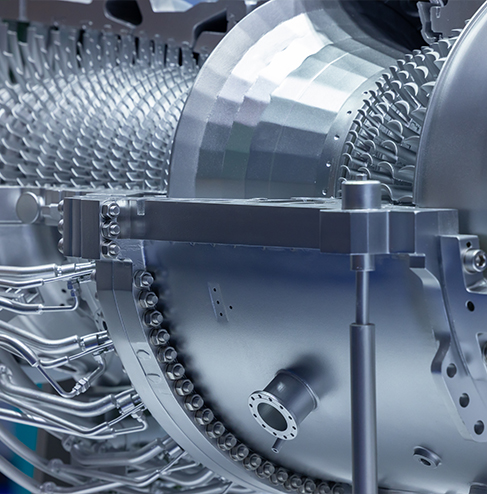

Gas Turbine Compressor Inspection Services

Precision Maintenance and Repair for Gas and Steam Turbine Systems

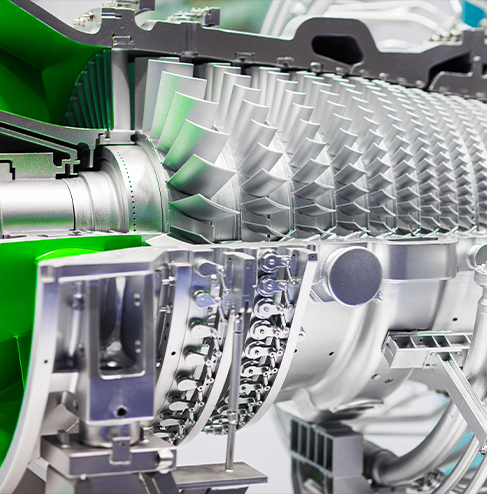

Comprehensive Turbine Inspection and Repair Services

At Advanced Turbine Support, we specialize in detailed turbine compressor inspection services for gas turbines, steam systems, and industrial gas power units. Our experts provide complete inspection, maintenance, and turbine repair with industry-leading precision to ensure reliability, safety, and consistent performance.

Each evaluation is handled by a skilled team trained to detect early-stage issues before they become costly or cause unplanned downtime. We focus on preventing outages, improving efficiency, and keeping your energy operations running at peak condition.

Gas Turbine Repair and Maintenance Solutions

Our gas turbine repair services are built to meet the high-performance demands of industrial gas turbine systems. We deliver comprehensive maintenance and repair programs designed to restore mechanical integrity and improve output efficiency.

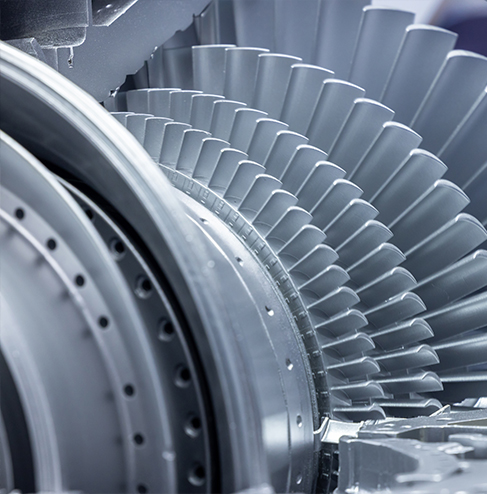

Capabilities include:

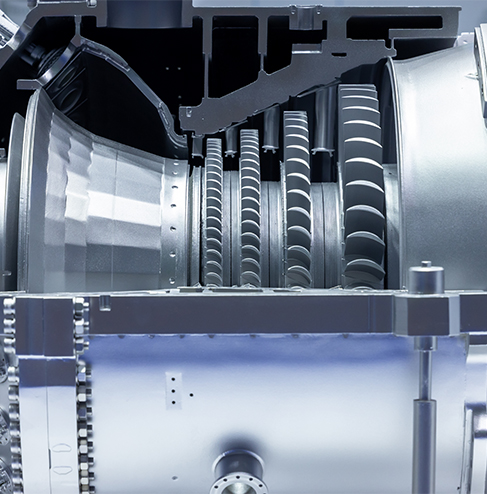

- Compressor Section Overhaul – Disassembly, cleaning, and reassembly of the compressor and rotor assemblies.

- Casing and Alignment Services – Precision alignment and balance correction to reduce vibration and extend equipment life.

- Vane and Blade Restoration – Repair and replacement of vanes, turbine blades, and seals damaged by combustion wear.

- Generator & Startup Support – On-site generator synchronization and post-startup performance verification.

We handle multiple gas turbine models and provide scheduled maintenance programs tailored to your operational environment.

Thorough Turbine Compressor Inspection Process

Our turbine inspection methodology integrates mechanical testing, borescope inspections, and quality control procedures to ensure a complete understanding of system condition.

Inspection process includes:

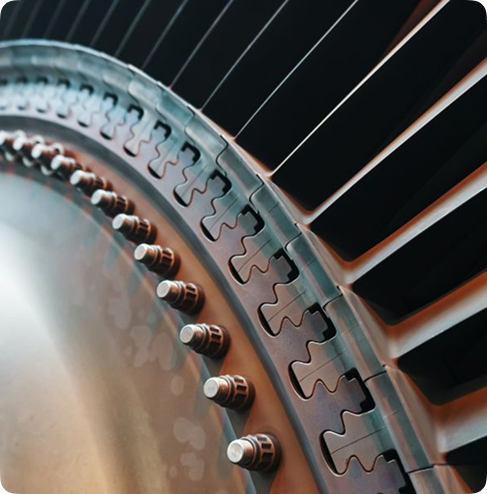

- Borescope Inspections – Internal inspection of compressor and rotor components for erosion, cracks, or distortion.

- Mechanical Evaluation – Detailed analysis of casing, alignment, and vibration to detect potential imbalances.

- Quality Control & Data Review – Thorough verification and documentation of results before sign-off.

- Final Report & Consultation – A comprehensive report issued within 24 hours to ensure operational transparency.

Our turbine services comply with stringent industry standards, providing maximum reliability and long-term equipment stability.

Industrial Turbine Overhaul and Restoration

When inspection identifies degradation, our team provides full overhaul and repair services to restore precision and integrity. We address rotor, vane, and casing areas using advanced machining and coating technologies.

Our restoration services include:

- Field Overhaul Programs – On-site or in-shop overhaul with immediate repair turnaround.

- Vibration & Balance Correction – Dynamic balancing to stabilize performance and reduce stress.

- Steam & Gas Turbine Maintenance – Combined maintenance support across steam and gas turbine assets.

- Alignment Verification – Ensuring every part meets design specifications and tolerances.

Our dedication to quality control and precision ensures every turbine leaves our care operating at full efficiency.

Minimizing Downtime Through Reliable Maintenance

Downtime can quickly disrupt production and profitability. Advanced Turbine Support helps clients minimize downtime with predictive maintenance programs that combine inspection, testing, and proactive scheduling.

Our engineers build detailed turbine services plans to ensure every compressor, combustion chamber, and generator meets performance requirements before and after operation. We specialize in rapid outage response and coordinated turnaround strategies to maintain plant continuity.

Why Choose Advanced Turbine Support

Trusted Experts in Turbine Compressor Repair and Maintenance

Complete Compressor & Turbine Repair Services

In-depth inspection, repair, and overhaul for rotating assemblies.

Gas Turbine Specialists

Precision repair for industrial gas turbine and steam units.

Field Service Expertise

Rapid deployment for on-site inspection and planned maintenance during outages.

Thorough Quality Control

Rigorous quality control procedures ensure long-term reliability.

compressor inspection & Repair

Powering Performance Through Precision

Your gas turbine’s performance defines your operation’s success—and every detail matters.

At Advanced Turbine Support, we don’t just inspect turbines; we optimize them for maximum efficiency, reliability, and uptime. Our comprehensive gas turbine compressor inspection services combine advanced technology, experienced technicians, and rapid turnaround to uncover hidden issues before they become costly failures.

From power generation to industrial applications, we deliver results that extend equipment life, boost output, and safeguard your bottom line.

Certifications

Gallery

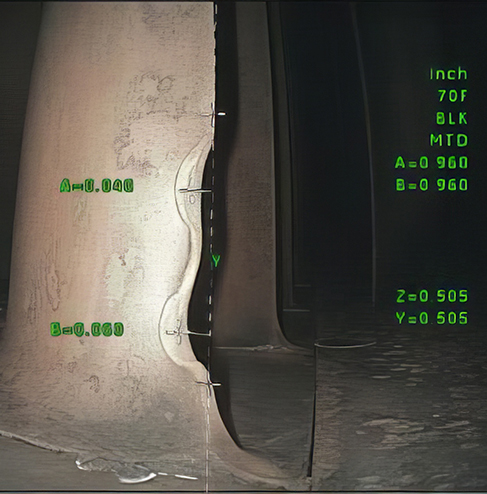

Dye Penetrant testing

At Advanced Turbine Support, every dye penetrant test represents our commitment to uncovering the smallest surface flaws with precision, ensuring your equipment operates safely and reliably under any condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule a Turbine Compressor Inspection Today

When it comes to gas turbine and steam system reliability, trust Advanced Turbine Support for fast, precise, and dependable service. Our turbine compressor inspection services deliver the insights and performance verification needed to keep your operation efficient, compliant, and safe.

Contact our team today to schedule your inspection or discuss upcoming turbine repair and maintenance projects.