Advanced Turbine Blade Blending and Repair Solutions

Advanced Turbine Support provides professional blending services designed to repair, restore, and optimize performance across a wide range of gas and industrial engine models.

Our skilled technicians perform precision in-situ blending utilizing perfected techniques to restore component geometry, optimize aerodynamic profiles, and mitigate stress concentrations—effectively reducing the risk of catastrophic engine failure and extending turbine life.

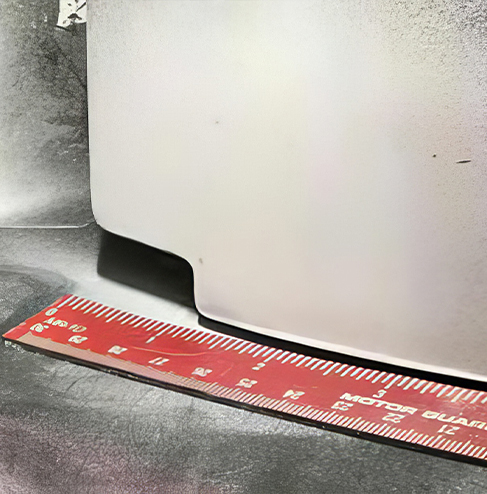

Blending is the process of reshaping and polishing affected areas on critical components — including compressor assemblies, rotors, and vanes — to restore geometry and balance without full replacement. Each blend is engineered to meet or exceed OEM standards for safety, performance, and reliability.

The Turbine Blending Process

Our proprietary blending process combines precision inspection, manual skill, and advanced tooling to ensure consistent results.

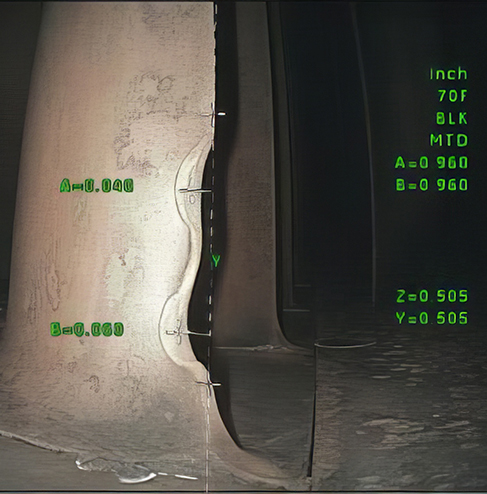

Before each project, our technicians conduct detailed borescope inspections and mapping of all damaged areas. Once blending begins, we remove imperfections and polish the surface to restore its aerodynamic profile.

The process includes:

- Evaluation and mapping of cracks, nicks, or fatigue along the leading edge or tip

- Controlled manual blending using precision stone and radius tools to maintain original geometry

- Polishing to improve airflow and efficiency

- Final non destructive testing to confirm all damage has been removed

Advanced Turbine Support specializes in in-situ repair, allowing restoration work to be completed without disassembling the engine or compressor. This economical approach minimizes downtime and maximizes output.

In-Situ Blending Capabilities

Our in-situ capabilities allow us to restore surfaces directly within the operating machine, reducing maintenance time and preserving alignment of rotating assemblies.

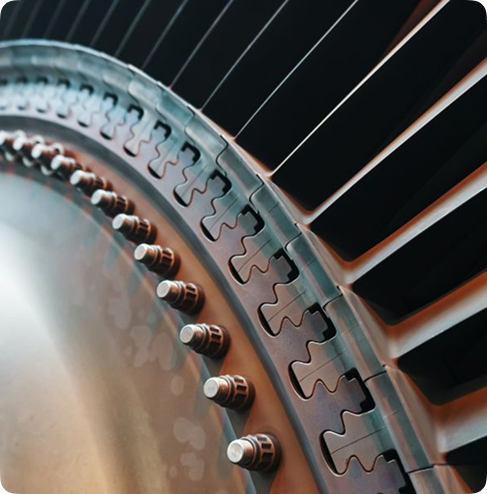

We provide precision blending for compressor rotors, stators, and fan assemblies across multiple OEM engine types, including GE, Siemens, MHI, Alstom, Pratt & Whitney, and Rolls Royce.

In-situ services include:

- Blend and re-profile of component defects and or damage

- Component surface restoration

- Removal of cracks, nicks, and fatigue to mitigate further damage

- Geometry correction to maintain smooth airflow through fully exposed components

Our team performs in-situ precision blending on gas turbines, targeting the first 7–11 compressor stages as well as steam turbine nozzles and high-pressure & intermediate sections for both turbofan and aero-derivative applications. This advanced process restores critical aerodynamic profiles, eliminates surface discontinuities that can induce flow separation, and mitigates stress concentrations—ensuring optimal compressor efficiency, structural integrity, and extended component life under all operating conditions.

Engine Damage Assessment and Prevention

Minor surface damage can lead to severe engine failure if not addressed promptly.

Our inspection and blending procedures are designed to measure and correct irregularities before they become structural problems.

Through routine borescope inspections and precision repair, we help operators avoid downtime and maintain peak turbine efficiency.

Common issues our technicians address include:

- Crack formation or deformation on fan or compressor sections

- Nick and trail wear from foreign object impact

- Surface fatigue or material corrosion in high-temperature stages

- Disk and wheel erosion affecting airflow and balance

Each repair is executed with precision to maintain OEM specifications, ensuring safe operation and extending equipment lifespan.

Why Choose Advanced Turbine Support

Your Trusted Partner for Turbine Blending and Repair

In-Situ Blending

Complete repair without disassembly for faster turnaround and reduced downtime.

Comprehensive Inspections

Detailed borescope inspections and damage mapping ensure precise, verified restoration.

Experienced Technicians

Backed by decades of experience across aviation, industrial, and gas turbine systems.

Economical and Reliable Solutions

Cost-effective blend services that extend the lifespan of each engine.

Blade Blending Services

Trusted Across Leading Turbine Brands

Advanced Turbine Support is trusted by operators worldwide to perform precision inspections, repairs, and blending services across all major turbine brands and models.

GE: LM2500, LM5000, LM6000, LMS100, Frame 3, 5, 6, 7B, 7E, 7EA, 7F, 7FA, 7H, 9F, 9FA

Siemens: 171, 191, 251, 301, 501 D5, D5A, AA, F, G, SGT6-5000F, V84.2, V94.3

MHI: M501G

Alstom: GT-8, GT11, GT24

Pratt and Whitney: FT-4, FT-8

Rolls Royce: Avon 200, Trent 60

Certifications

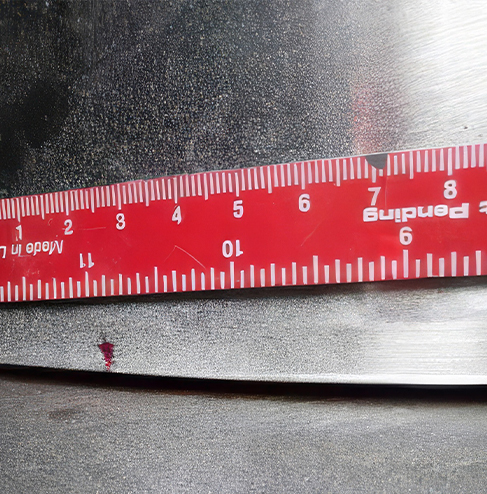

Gallery

Turbine blade blending services

At Advanced Turbine Support, every inspection is more than a procedure — it’s a promise of performance, safety, and precision. With our proven inspection process, cutting-edge borescope equipment, and dedicated inspectors, you’ll gain the confidence that comes from knowing your systems are in optimal condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule Your Turbine Blending Service Today

When your equipment shows signs of damage or wear, trust Advanced Turbine Support to deliver precision blending services that restore balance, efficiency, and performance.

We perform every repair safely, accurately, and in compliance with OEM and industry standards.

Contact us today to schedule a blending or inspection service and experience the most advanced restoration solutions available.