Hot Gas Path Inspection Services

Comprehensive Gas Turbine Maintenance for Peak Performance and Reliability

Gas Turbine Hot Gas Path Inspection Experts

A hot gas path inspection (HGPI) is one of the most critical maintenance procedures for ensuring gas turbine performance, reliability, and safety. During a hot gas path inspection, our engineers and technicians evaluate every component exposed to high temperature gases within the combustion system—including blades, nozzles, liners, and casings—to identify signs of wear, erosion, or distortion.

Advanced Turbine Support provides complete gas turbine maintenance and inspection services for power plants and industrial facilities worldwide, ensuring maximum uptime and efficiency.

What Is a Hot Gas Path Inspection?

A hot gas path refers to the section of the gas turbine where combustion gases flow through the turbine’s high-temperature regions. The hot gas path inspection process involves disassembling specific turbine sections to inspect internal parts like rotors, stators, blades, and nozzles for thermal stress, cracking, or material degradation.

This type of inspection provides valuable insight into turbine health and helps engineers plan repairs, replacements, or overhaul schedules based on actual component condition rather than assumption.

Comprehensive Scope of Inspection

Our HGPI scope covers all critical areas of the turbine’s hot gas path. Each inspection is performed by qualified engineers and technicians using specialized tools and optical equipment.

Inspection scope includes:

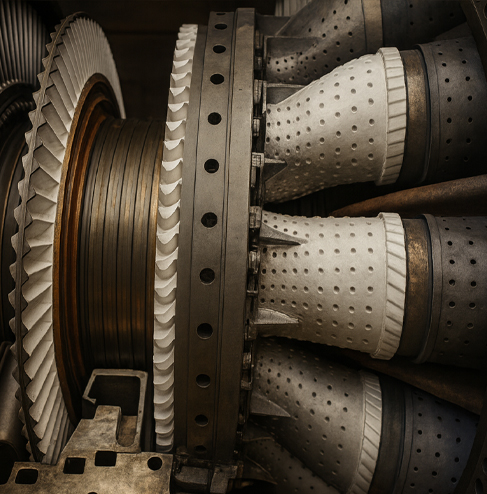

- Combustion Section: Examine combustion liners, transition pieces, and fuel nozzles for hot spots, warping, and cracks.

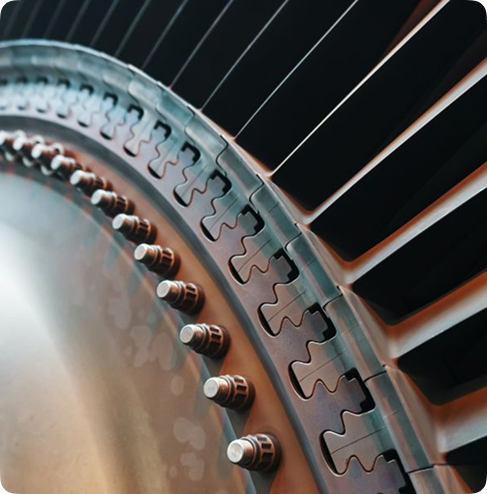

- Turbine Section: Inspect blades, rotors, and stators for tip rubbing, bowing, and thermal fatigue.

- Compressor Section: Evaluate compressor blades and casing for fouling, erosion, and clearance issues.

- Seals & Bearings: Check for leakage, wear, and proper clearance alignment.

Each inspection concludes with a detailed condition report and recommendations for repair, replacement, or continued service.

Why Hot Gas Path Inspections Are Essential for Gas Turbine Maintenance

Gas turbine maintenance relies on regular HGPI intervals to detect degradation caused by extreme operating conditions. High temperature, combustion, and fuel impurities accelerate wear on turbine parts—especially nozzles, liners, and blades.

A properly scheduled hot gas path inspection helps prevent catastrophic failures, improves turbine availability, and reduces costly unplanned outages. Typically, CI (Combustion Inspections) occur every 8,000 hours, and HGPI is recommended every 24,000 hours or four years, depending on the turbine model and fuel type.

Our Inspection Process

At Advanced Turbine Support, our inspection process combines precision, experience, and efficiency.

- Disassembly & Preparation: Turbine sections are opened and cleaned to expose combustion and hot gas path parts for detailed analysis.

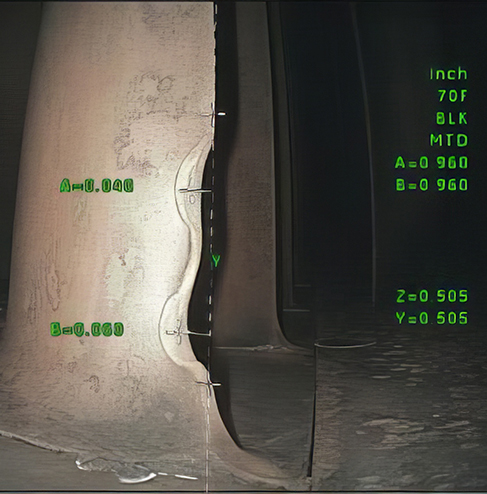

- Visual & Borescope Evaluation: Our technicians inspect each component for cracks, corrosion, or coating loss.

- Dimensional & Clearance Checks: We measure casing, blade, and rotor dimensions to confirm proper fit and thermal clearance.

- Documentation & Reporting: A full photographic and written report is delivered within 24 hours, highlighting all findings and recommended repairs or overhaul actions.

This proactive approach ensures every inspection supports long-term reliability and performance.

Why Choose Advanced Turbine Support

Trusted Gas Turbine Inspection Specialists

Comprehensive Hot Gas Path Inspections

Full evaluation of combustion, rotor, blade, and casing integrity.

Experienced Field Engineers

20+ years performing gas turbine maintenance and HGPI worldwide.

Reduced Downtime

Optimized inspection schedule to minimize disruption and improve turbine uptime.

Fast Turnaround Reports

Complete inspection documentation delivered within 24 hours.

Hot Gas Path Inspections

Hot Gas Path Inspection Scheduling and Frequency

Maintaining a proactive inspection schedule is essential for turbine longevity. Our team coordinates with plant managers to align HGPI and CI intervals with operational cycles, outage windows, and seasonal demand.

We also offer flexible inspection services that include remote or on-site support for facilities running gas turbines of all OEM types. Whether you operate GE, Siemens, or Mitsubishi units, we customize each inspection to meet your operational needs and budget.

Experienced Engineers, Rapid Reporting

Our experienced engineers understand that downtime costs can reach millions per day. That’s why we deliver every hot gas path inspection report within 24 hours of completion—giving operators immediate visibility into their turbine’s condition.

We maintain inspection teams strategically located across North America, the Caribbean, Europe, and the Middle East, ensuring fast mobilization for emergency gas turbine maintenance or planned outages.

Certifications

Gallery

Hot Gas Path Experts

At Advanced Turbine Support, every dye penetrant test represents our commitment to uncovering the smallest surface flaws with precision, ensuring your equipment operates safely and reliably under any condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule Your Hot Gas Path Inspection Today

When you need dependable gas turbine maintenance, trust the experts at Advanced Turbine Support. Our team performs every hot gas path inspection with precision, care, and efficiency—helping you extend turbine life, optimize performance, and prevent costly failures.

Contact us today to schedule your next hot gas path or combustion inspection and keep your operation running safely and efficiently.