why borescope inspections are crucial for safety and reliability

Every inspection matters — especially when it comes to the performance of engines and internal components that power your operation. Regular borescope inspections give you a detailed internal view of hard-to-reach areas without disassembly.

Whether you operate aircraft engines, power generation systems, or industrial equipment, these nondestructive type of inspections help detect surface defects, foreign objects, or blockages that compromise efficiency and safety. By combining visual evidence with expert analysis, our team ensures regulatory compliance, reduces the risk of downtime, and protects the integrity of your assets.

Our Full Range of Borescope Inspection Services

We provide a full range of inspection services designed to meet the needs of various industries — including aerospace, energy, manufacturing, and oil and gas.

Our team specializes in:

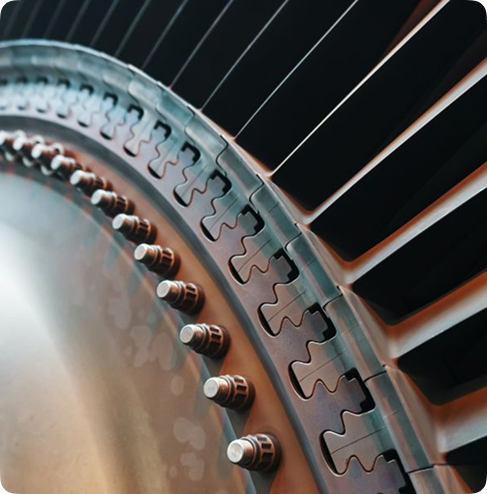

- Turbine inspection for gas turbines, steam turbines, and combustion chambers

- Boiler inspection to assess internal scaling, pitting, and corrosion

- Pipeline and tank inspection using video borescopes and robotic crawlers

- Engine component inspection for detecting cracks and defects in rotating parts

- On-site inspection services for scheduled maintenance or emergency outage support

These borescope video inspection services are non-destructive (NDT), giving you clear, real-time images for accurate condition assessment and quality assurance across every application.

Borescopes For All Your Inspection Needs

When precision matters, borescope inspections provide the clarity and confidence your operation depends on. Using advanced video borescope equipment and inspection cameras, our experienced inspectors perform detailed visual inspections that navigate tight spaces to reach even the most hard-to-reach components within turbines, boilers, and pipelines. Borescopes are relied upon for:

- Pre-commissioning

- Outage planning

- Baseline inspections

- Emergent issues and forced outages

- Semi-annual or annual maintenance

- Time-sensitive assessments

- Condition-based maintenance

- Post-overhaul verification

Each inspection delivers actionable data to help you avoid costly repairs and keep critical systems performing at peak efficiency.

Advanced Equipment and Technology

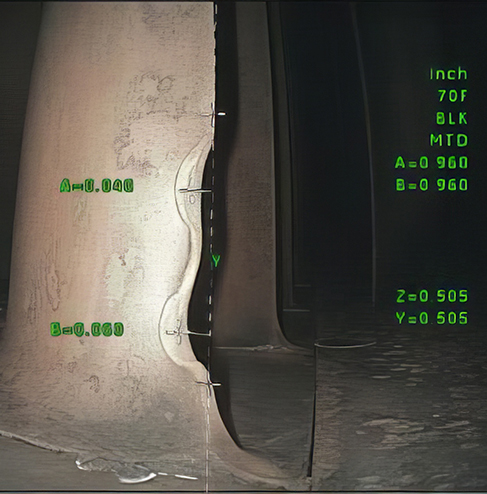

At the heart of every inspection is precision technology. We use cutting-edge borescope equipment — both flexible and rigid — to inspect and navigate hard-to-reach areas.

Our video borescopes and inspection cameras deliver high-resolution video and real-time feedback to our inspectors, allowing for immediate identification of irregularities, discontinuities, or defects. With robotic crawlers, probes, and inspection tools, we can safely inspect confined spaces, tight bends, or internal structures without dismantling equipment.

Each piece of inspection equipment undergoes strict calibration to maintain high-quality performance and accurate measurement results.

Comprehensive Nondestructive testing (NDT) methods

As part of our inspection process, we integrate multiple nondestructive testing (NDT) techniques to complement our borescope inspections and enhance quality assurance. These include:

- Magnetic particle testing for identifying surface and near-surface defects in ferromagnetic materials

- Liquid penetrant and penetrant testing for locating fine surface defects such as cracks and discontinuities

- Hardness testing to measure material integrity and detect irregularities in engine components

- Visual inspection for identifying surface defects, weld issues, and corrosion

By combining borescope inspection with these NDT techniques, we provide a complete picture of equipment health and reliability.

Why Choose Advanced Turbine Support

Our inspection process is built around accuracy, safety, and speed. Here’s what you can expect when you schedule your inspection with Advanced Turbine Support:

Unmatched Experience

With over 25 years of inspection expertise and 40,000+ hours in the field, our experienced inspectors deliver precision, accuracy, and insight you can rely on for every turbine, pipeline, and boiler inspection.

Comprehensive Solutions

From borescope inspection services and remote visual inspections to full nondestructive testing (NDT) capabilities - we provide a full range of inspection solutions to meet any requirement.

Advanced Equipement & Calibration

Our borescope equipment, inspection cameras, and robotic crawlers are calibrated to the highest industry standards; ensuring high-resolution, real-time data for confident maintenance decisions.

24/7 Global Coverage & Rapid Response

We’re available around the clock, worldwide. Whether you need pre-commissioning, outage support, or time-sensitive assessments, our teams mobilize quickly to deliver results.

Borescope

Inspections

Trusted across leading turbine brands

Experienced inspectors who have been in the industry for years complete our NDE borescope inspection services. Our team brings unmatched experience across a wide range of turbine models and OEMs, including:

GE: LM2500, LM5000, LM6000, LMS100, Frame 3, 5, 6, 7B, 7E, 7EA, 7F, 7FA, 7H, 9F, 9FA

Siemens: 171, 191, 251, 301, 501 D5, D5A, AA, F, G, SGT6-5000F, V84.2, V94.3

MHI: M501G

Alstom: GT-8, GT11, GT24

Pratt and Whitney: FT-4, FT-8

Rolls Royce: Avon 200, Trent 60

Borescopes For All Your Inspection Needs

When precision matters, borescope inspections provide the clarity and confidence your operation depends on. Using advanced borescope equipment and inspection cameras, our experienced inspectors perform detailed visual inspections that reach even the most hard-to-reach components within turbines, boilers, and pipelines. Borescopes are relied upon for:

- Pre-commissioning

- Outage planning

- Baseline inspections

- Emergent issues and forced outages

- Semi-annual or annual maintenance

- Time-sensitive assessments

- Condition-based maintenance

- Post-overhaul verification

Each inspection delivers actionable data to help you avoid costly repairs and keep critical systems performing at peak efficiency.

Certifications

Gallery

Borescope

Inspections

At Advanced Turbine Support, every inspection is more than a procedure — it’s a promise of performance, safety, and precision. With our proven inspection process, cutting-edge borescope equipment, and dedicated inspectors, you’ll gain the confidence that comes from knowing your systems are in optimal condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule your borescope inspection today

If your facility relies on turbines, engines, or industrial systems, you can’t afford to overlook inspection. Preventive borescope inspections are crucial for safety, efficiency, and long-term reliability.

Whether you need a remote visual inspection of a hard-to-reach area, a detailed pipeline assessment, or a complete boiler inspection, our team has the equipment available, expertise, and precision tools to handle it.

Contact Advanced Turbine Support today to schedule your inspection and discover why leading companies in power generation and aerospace trust us for borescope inspection services that deliver results — in real time.