Turbine Blend, Polish, Peen Services

Precision Turbine Rotor Repair and Surface Enhancement

Comprehensive turbine rotor repair services

Advanced Turbine Support delivers expert turbine blend, polish, and peen repair services for gas turbine, steam turbine, and aeroderivative applications.

Our team provides both field service and in-shop overhaul programs tailored to OEM specifications, extending the life of your critical turbine components while improving performance and corrosion resistance.

Regardless of your Gas Turbine type, our technicians perform advanced rotor and turbine component restoration using proprietary polishing processes.

The Turbine Blend, Polish, and Peen Process

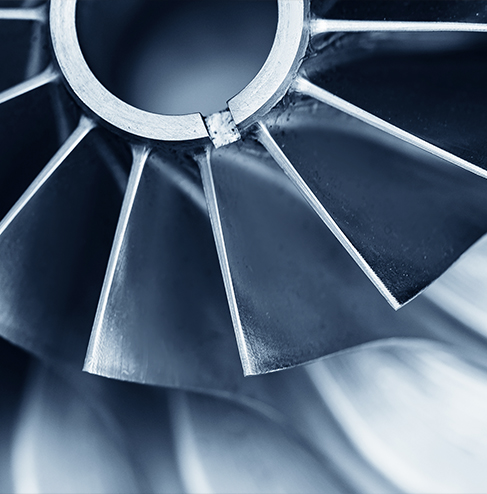

Our blend, polish, and peen (BPP) procedure restores the edge condition and surface integrity of turbine wheels, discs, and rotors.

The process is engineered to meet manufacture specifications, prevent crack initiation, and minimize stress concentration in high nickel alloys commonly found in F-class turbines.

-

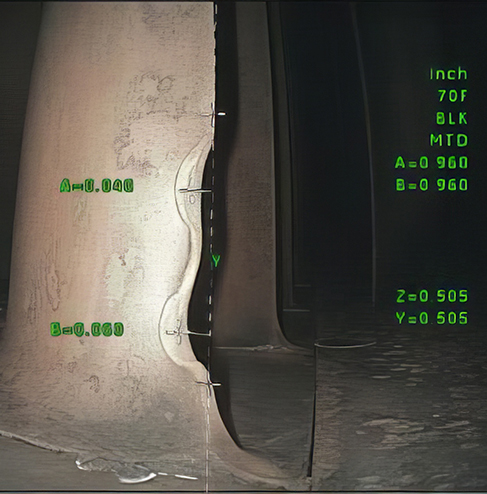

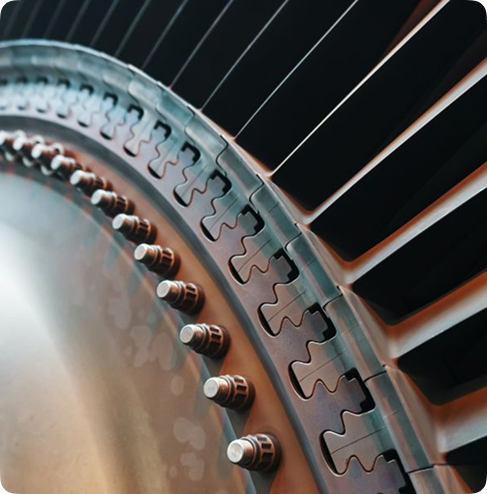

Blending: Technicians reshape and remove surface imperfections, providing an ideal radius along cooling slots and dovetail edges.

-

Polishing: Each surface is refined to a mirror-like finish that enhances adhesion and reduces the likelihood of crack propagation.

-

Peening: Using advanced flapper peening methods and the latest technology, compressional forces are applied to strengthen the surface layer and mitigate initiation of fatigue.

All steps are verified using penetrant inspection and fluorescent NDE methods to confirm full coverage and eliminate subsurface indications before final approval.

Turbine Rotor Management and Overhaul Capabilities

Advanced Turbine Support combines rotor management expertise with advanced diagnostics and manufacture-grade repair services.

Our goal is to extend the life of your rotor through systematic inspection, maintenance, and refurbishment.

We perform:

- In-situ inspection and surface diagnostics for compressor and rotors

- Disc and dovetail slot restoration using precision blast and polish systems

Trusted Expertise Across Leading Gas Turbine Brands

From GE and PSM units to Siemens, Alstom, and MHI systems, Advanced Turbine Support services all major OEMs with unmatched precision.

Our technicians handle everything from 7F and 9E frames to aeroderivative models, applying OEM-level processes to restore surface integrity and ensure long-term durability.

Each project is documented for quality assurance, with before-and-after imagery and detailed inspection reports to maintain full traceability.

Why Choose Advanced Turbine Support

Your Partner for Precision Turbine Restoration and Rotor Management

Comprehensive BPP Services

Expert blend, polish, and peen for rotors, blades, and discs.

NEED NEW POINT HERE

Here is the text section.

In-Situ Repair Capability

On-site field service and inspection without disassembly.

Rotor Management Expertise

Systematic diagnostics and overhaul programs for GE and other OEM engines.

Blend, Polish, & Peen Services

Trusted Across Global Turbine Fleets and Engine Models

Advanced Turbine Support delivers precision blend, polish, and peen repair services across the world’s leading gas and steam turbine platforms.

Our technicians are trained to inspect, restore, and maintain rotors, discs, and blades across diverse OEM designs — ensuring reliable performance and extended equipment life.

We proudly support:am brings unmatched experience across a wide range of turbine models and OEMs, including:

GE: LM2500, LM5000, LM6000, LMS100, Frame 3, 5, 6, 7B, 7E, 7EA, 7F, 7FA, 7H, 9F, 9FA

Siemens: 171, 191, 251, 301, 501 D5, D5A, AA, F, G, SGT6-5000F, V84.2, V94.3

MHI: M501G, 501F, 501J

Alstom: GT-8, GT11, GT24

Pratt and Whitney: FT-4, FT-8

Rolls Royce: Avon 200, Trent 60

Certifications

Gallery

Borescope

Inspections

At Advanced Turbine Support, every inspection is more than a procedure — it’s a promise of performance, safety, and precision. With our proven inspection process, cutting-edge borescope equipment, and dedicated inspectors, you’ll gain the confidence that comes from knowing your systems are in optimal condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule a Turbine Blend, Polish, Peen Service Today

When precision matters, trust Advanced Turbine Support to deliver blend, polish, and peen services that restore performance, prevent crack formation, and ensure operational reliability.

We provide on-site and facility-based services to meet the needs of every operator, reducing risk and maximizing asset longevity.

Contact us today to discuss your next rotor repair or overhaul project.