Aeroderivative Gas Turbine Services

Global Inspection, Repair, Overhaul, and Maintenance Solutions for High-Performance Gas Turbines

Comprehensive Aeroderivative Gas Turbine Support

Advanced Turbine Support, we specialize in aeroderivative gas turbine services designed to improve reliability, enhance efficiency, and reduce operational downtime. With over 25 years of experience, our engineers and technicians provide end-to-end turbine services—from inspection and component repair to overhaul and system upgrade.

Our goal is simple: to deliver quality aeroderivative gas turbine support that ensures continuous operation and long-term performance for operators in power generation, marine, and industrial sectors worldwide.

Trusted Aeroderivative Gas Turbine Repair & Overhaul Services

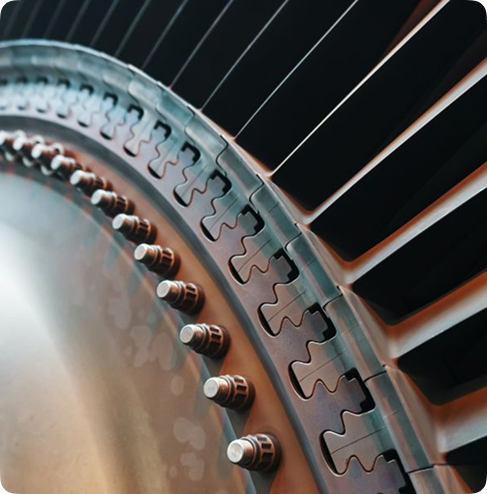

Whether it’s a Pratt & Whitney, Mitsubishi, GE, Avon, or Rolls-Royce turbine, our team has the expertise to inspect, assess, and deliver fast, cost-effective repair solutions for your gas turbine.

Working alongside key industry partners that maintain ISO 9001:2015 certifications, we provide comprehensive repair and overhaul services for every major component of your aeroderivative gas turbine, ensuring peak performance and OEM compliance.

Our combined capabilities include:

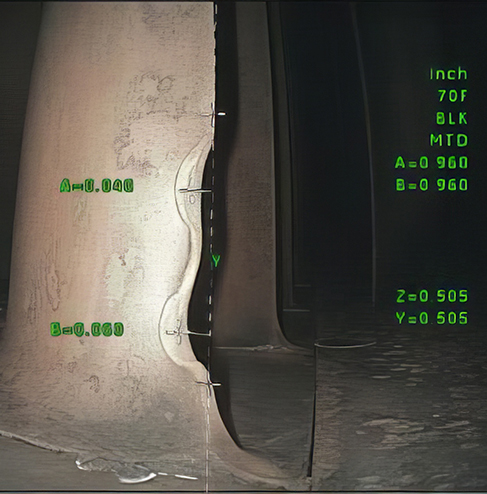

- Visual & Borescope Evaluation: Our technicians inspect each component for cracks, corrosion, or coating loss.

- Dimensional & Clearance Checks: We measure casing, blade, and rotor dimensions to confirm proper fit and thermal clearance.

- Documentation & Reporting: A full photographic and written report is delivered within 24 hours, highlighting all findings and recommended repairs or overhaul actions

- Field Service & Diagnostics: On-site troubleshooting and condition monitoring for real-time issue resolution.

This proactive approach ensures every inspection supports long-term reliability and performance

Aeroderivative Gas Turbine Maintenance and Reliability Solutions

Gas turbines operate in demanding environments where performance depends on proactive turbine maintenance and data-driven condition tracking. Our aeroderivative gas turbine services ensure maximum availability and uptime through detailed inspection and preventive maintenance service programs.

We help operators plan turnarounds, coordinate overhaul timelines, and execute maintenance strategies that maintain reliability while minimizing downtime. Every project is handled by certified technicians and engineers following proven turbine support methodologies.

Why Choose Advanced Turbine Support

Trusted Gas Turbine Inspection Specialists

Comprehensive Hot Gas Path Inspections

Full evaluation of combustion, rotor, blade, and casing integrity.

Experienced Field Engineers

20+ years performing gas turbine maintenance and HGPI worldwide.

Reduced Downtime

Optimized inspection schedule to minimize disruption and improve turbine uptime.

Fast Turnaround Reports

Complete inspection documentation delivered within 24 hours.

Aeroderivative maintenance

The Global Standard in Aeroderivative Gas Turbine Performance

When downtime isn’t an option, Advanced Turbine Support delivers. Our aeroderivative gas turbine services are engineered for maximum reliability, precision, and uptime—whether you’re powering a fleet, facility, or global operation.

Backed by decades of expertise and proven field results, we combine advanced diagnostics, OEM-level repair, and rapid deployment to restore power fast and keep your assets performing at peak efficiency.

From inspection to overhaul, we help you protect your investment, extend turbine life, and achieve world-class operational performance.

Certifications & Qualifications

Gallery

Aeroderivative maintenance

At Advanced Turbine Support, every dye penetrant test represents our commitment to uncovering the smallest surface flaws with precision, ensuring your equipment operates safely and reliably under any condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule Your Hot Gas Path Inspection Today

When you need dependable gas turbine maintenance, trust the experts at Advanced Turbine Support. Our team performs every hot gas path inspection with precision, care, and efficiency—helping you extend turbine life, optimize performance, and prevent costly failures.

Contact us today to schedule your next hot gas path or combustion inspection and keep your operation running safely and efficiently.