Categories

Secure Multi Party Computation

The Compiler

Uncategorized

Book Your

Consultation

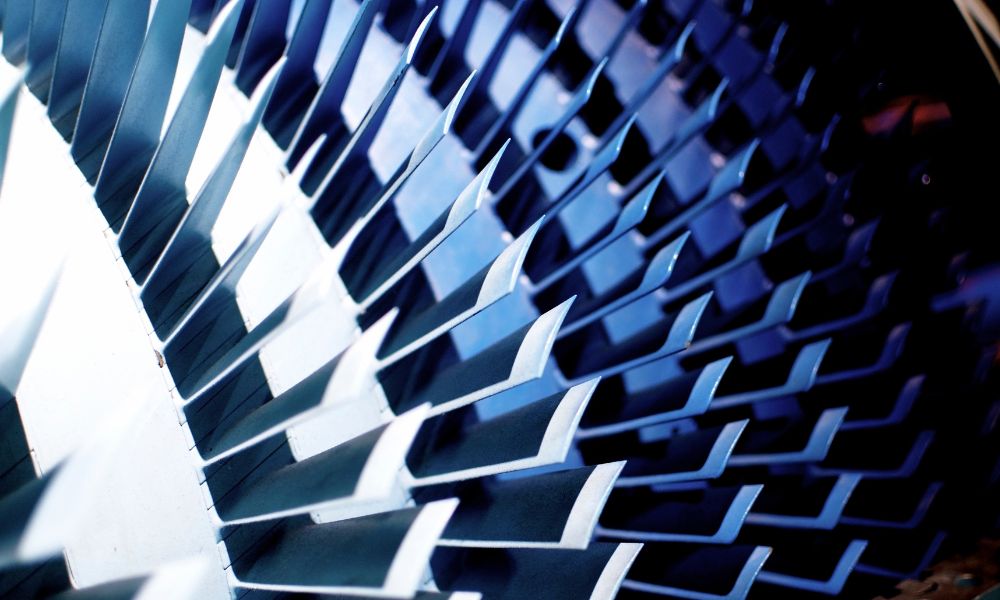

Most electrical power on Earth comes from a turbine. These turbines have different ways to power up, whether it’s steam, gas, water, or wind. All turbine blades will deal with issues after a certain period, but this blog will focus on gas turbines.

There are a few common defects commonly found in gas turbine blades. These parts undergo loads of stress from the gas turbine.

Corrosion

Most outages occur in gas turbines due to blade corrosion. Properly coating and cleaning the blades can help reduce erosion and extend their lives. Chromium sulfide, complex sulfides, and oxide are chemical compounds that greatly affect turbine blades and reduce their fatigue strength.

The material used to create the blade will also determine corrosion damage. Manufacturers should use corrosion-resistant alloys to combat this defect.

Overheating

Overheating in gas blade turbines promotes creep. What is creep, you may ask? According to an educational article, it’s the permanent deformation of turbine structures caused by high temps when the stress is less than yield strength. The creep encourages intergranular cracks on the blades and shortens their lifespan.

Fatigue

Gas turbine blades are under a lot of stress. They undergo contrasting temperatures during the start-up and shutdown processes, which causes thermal fatigue. Not only does fatigue affect the blades, but it also harms the gas turbine itself.

Fatigue in turbine blades can lead to cracks and turbine failure. These blades operate at high speeds; it’s no wonder they sustain cracks and tire easily.

What Is a Gas Turbine?

A gas turbine produces electricity by heating a mixture of fuel and air to high temperatures to spin the turbine blades. It efficiently creates electricity when used with a steam turbine, like a power plant.

The gas turbine has three main sections: the combustion system, the turbine, and the compressor. It contains an elaborate assortment of rotating and stationary aerofoil section blades. The compressor draws in air to pressurize within the engine. From the engine, the pressurized air goes into the combustion chamber at hundreds of miles per hour.

Ensure proper care for your gas turbine blades to avoid common defects. Contact Advanced Turbine Support for our expert turbine blade blending services. Our combined experience and equipment will ensure a job well done.

Next Posts

admin March 22, 2023

admin March 7, 2023

admin February 22, 2023