Ultrasonic & Phased Array Ultrasonic Inspection Services (UT & PAUT)

Advanced Non-Destructive Testing for Corrosion, Welds & Wall Thickness Measurement

Comprehensive Ultrasonic Testing (UT) Solutions Across Industries

Ultrasonic testing (UT) is a highly accurate non-destructive testing (NDT) method that uses high-frequency sound waves to detect internal flaws, measure wall thickness, and verify weld integrity. By transmitting ultrasonic waves into a test material, any reflected signals—called echoes—reveal discontinuities, defects, or corrosion below the surface.

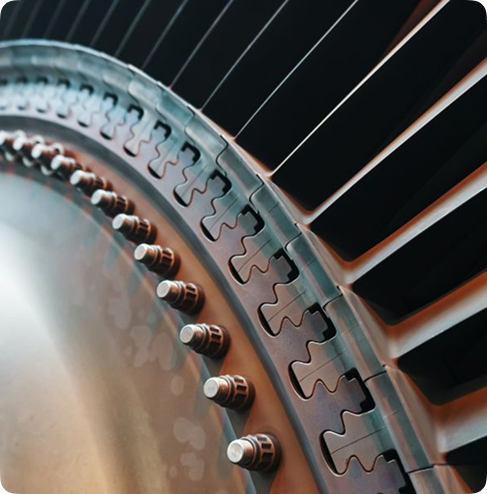

At Advanced Turbine Support, our ultrasonic inspection services are trusted across industries including aerospace, energy, and manufacturing to ensure reliability, safety, and precision in every component we inspect.

Phased Array Ultrasonic Testing for Complex Geometries

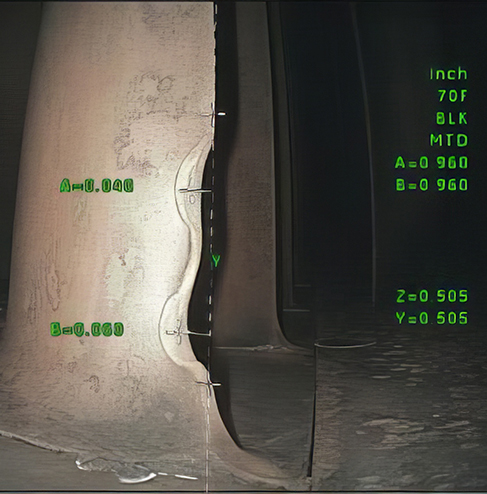

Phased array ultrasonic testing (PAUT) provides a more advanced level of flaw detection and thickness measurement than conventional UT. By electronically steering multiple probes and transducers, our technicians can inspect complex geometries, welds, and pipes with unmatched accuracy.

Phased array UT inspection services deliver:

- High-resolution imaging and advanced flaw detection

- Full thickness measurement for erosion and corrosion mapping

- Rapid coverage of large components with precise size and location data

- Accurate defect detection without disassembly

This ultrasonic testing method provides immediate data visualization for reliable inspection and maintenance decisions.

How Ultrasonic Testing Works

During ultrasonic inspection, a transducer sends ultrasonic waves or sound waves into the test object. When these waves encounter a discontinuity, part of the wave energy reflects back to the transducer, while the rest continues through the material. The reflected signal’s amplitude and time delay reveal the size and location of the flaw or defect.

UT inspection is versatile—it can detect internal flaws, measure thickness, and assess weld quality without damaging the test material.

Pulse-Echo and Immersion Testing Techniques

Our team performs pulse-echo and immersion testing methods depending on the application.

- Pulse-Echo UT – Measures wall thickness and identifies internal defects by capturing echoes reflected from inside surfaces.

- Advanced Phased Array Testing – Utilizing contact transducers and probes with multiple active elements allows inspectors to optimize signal responses on complex geometry components.

These ultrasonic testing techniques provide precise detection of discontinuities, inclusions, and flaws across a wide range of materials and component types.

Why Choose Advanced Turbine Support

Trusted Gas Turbine Inspection Specialists

Comprehensive Hot Gas Path Inspections

Full evaluation of combustion, rotor, blade, and casing integrity.

Experienced Field Engineers

20+ years performing gas turbine maintenance and HGPI worldwide.

Reduced Downtime

Optimized inspection schedule to minimize disruption and improve turbine uptime.

Fast Turnaround Reports

Complete inspection documentation delivered within 24 hours.

Ultrasonic Testing

Advantages of Phased Array and Conventional UT Inspection

Phased array and conventional ultrasonic testing are among the most efficient NDT methods available today. Both provide precise data visualization, increased accuracy, and fast inspection turnaround for critical components.

Advantages include:

- High-resolution flaw detection and accurate thickness measurement

- Detects internal flaws, discontinuities, and corrosion

- Suitable for pipes, welds, composites, and complex geometries

- Real-time imaging for improved maintenance planning

- Fully compatible with automated UT and digital reporting systems

Ultrasonic Testing Equipment and Probes

We use precision transducers, probes, and automated UT systems designed for flaw detection in composite, metallic, and ferrous materials. Each ultrasonic testing solution is tailored to your specific testing method, whether for pipe integrity, casting, or aerospace components.

Our technicians interpret ultrasonic wave data in real time, ensuring reliable defect detection and measurable thickness verification for every part inspected.

Certifications

Gallery

Ultrasonic Testing

Each inspection follows detailed quality assurance protocols to guarantee accuracy, traceability, and reliable flaw detection results.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule an Ultrasonic or Phased Array UT Inspection

Ensure your turbines, pipes, and welds meet the highest safety and reliability standards. Our ultrasonic testing solutions and phased array ultrasonic inspections deliver unmatched flaw detection, thickness measurement, and non-destructive testing accuracy.

Contact Advanced Turbine Support today to schedule your UT inspection and discover how our inspection services can extend your equipment’s life and improve uptime.