Eddy Current Testing Services

Precision Non-Destructive Testing for Turbines, Aerospace & Industrial Equipment

Why Eddy Current Inspections Are Crucial for Safety and Reliability

Eddy current testing is one of the most powerful non-destructive testing (NDT) techniques used to detect hidden defects, cracks, and corrosion in conductive materials. Using the principles of electromagnetic induction, our eddy current inspections help identify flaws before they compromise structural integrity or operational performance.

Because this inspection method doesn’t require component removal or surface preparation, it’s ideal for turbine inspections, aerospace welds, and industrial equipment that demand continuous uptime.

Our Full Range of Eddy Current Testing Services

At Advanced Turbine Support, we provide comprehensive eddy current testing services to meet the most demanding inspection requirements. From advanced eddy current array (ECA) to bolt hole inspections, our team delivers accurate results that minimize downtime and improve asset reliability.

Our ECT solutions include:

- Eddy Current Array Inspection – Multi-channel arrays for high-resolution crack detection and corrosion detection.

- Bolt Hole & Weld Inspections – Detect hidden defects or fatigue cracks in welds, joints, and bolted assemblies.

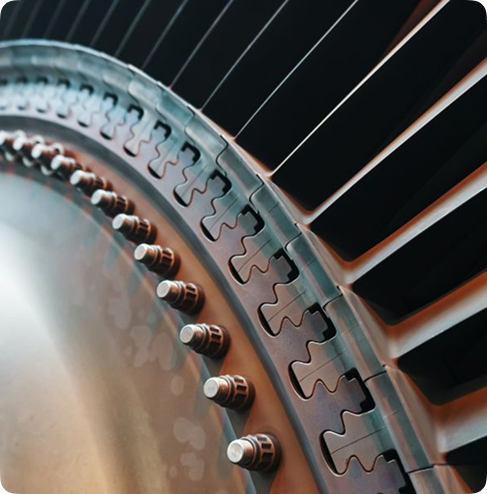

- Aerospace & Turbine Applications – Specialized eddy current techniques for thin materials and complex geometries.

Eddy Current Probes for All Your Inspection Methods

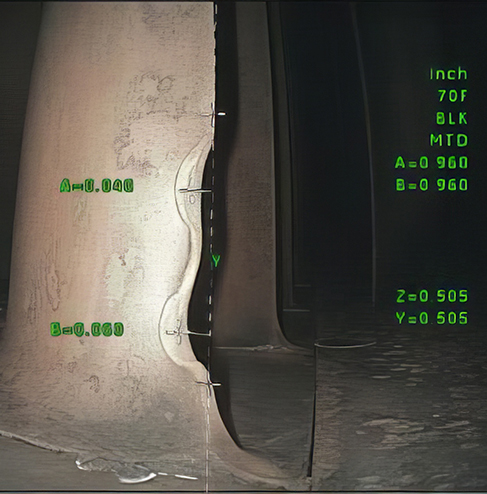

Our technicians use precision probes and coils to generate controlled magnetic fields that interact with the surface of conductive materials. When an irregularity disrupts this alternating current field, the eddy currents change—revealing critical details about the component’s condition.

Eddy current probes are flexible and adaptable, allowing us to inspect rotors, casings, airfoils, and welds in confined spaces. Whether performing tube inspection, surface scanning, or corrosion detection, our technology ensures the highest level of accuracy and quality assurance.

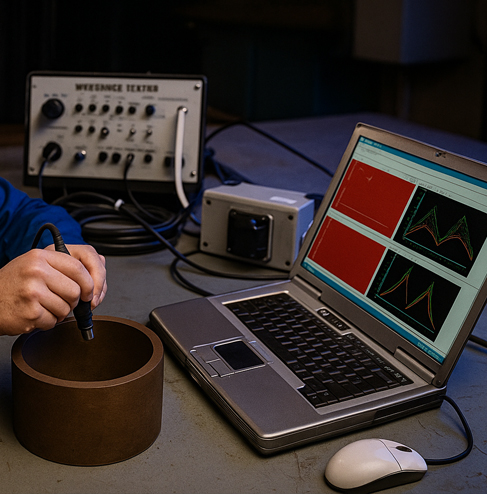

Advanced Equipment and Eddy Current Technology

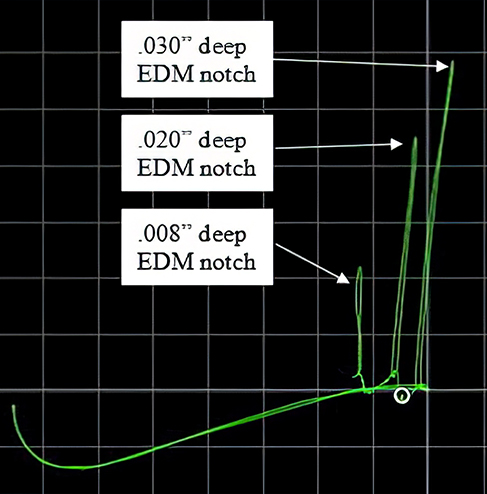

Our eddy current testing systems utilize advanced electromagnetic and array-based technologies designed to detect defects at varying depths and surface conditions. We use Eddy Current Array (ECA) systems capable of mapping components in two and even three dimensions, producing detailed imagery for condition analysis.

We can inspect through coatings and insulation without damaging the surface. This approach eliminates the need for disassembly—reducing testing time and cost. Our encoded eddy current technology provides high-fidelity data visualization and automated reporting for unparalleled reliability.

Comprehensive Non-Destructive Testing (NDT) Methods

Advanced Turbine Support combines eddy current tests with other nondestructive testing services, including liquid penetrant, magnetic particle, and visual inspections. This integrated testing method ensures a full understanding of your turbine’s or component’s condition.

Advantages of Eddy Current Testing:

- Detects cracks, pits, and corrosion without removing coatings

- Works on all conductive materials and alloys

- Produces immediate results for on-site decisions

- Supports both preventative maintenance and failure analysis

Why Choose Advanced Turbine Support

Trusted Experts in Eddy Current and NDT Inspections

Advanced Eddy Current Techniques

Proprietary inspection methods using phased and encoded eddy current arrays.

Fast, Reliable Results

Reduce a 4-week inspection to a 2-day in-situ evaluation.

Unmatched Field Experience

Decades of turbine and nondestructive testing expertise.

Safety & Quality Assurance

Meets the highest inspection and NDT standards across industries.

Eddy Current Testing

Trusted Across Leading Turbine Brands

Our eddy current testing services are trusted by turbine operators and OEMs across the globe. Whether inspecting rotors, airfoils, or bolt holes and bores, we use proven eddy current techniques and certified NDT procedures to ensure compliance and reliability.

Our technicians understand the intricacies of eddy currents, electromagnetic fields, and conductivity variations that can signal subsurface defects. Each inspection is tailored to your application—delivering actionable data that keeps your systems operating safely and efficiently.

Certifications

Gallery

Eddy Current Testing

With Advanced Turbine Support’s eddy current testing, you get thorough, high-precision flaw detection that helps keep your equipment running safely and reliably — no matter how demanding the application.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule Your Eddy Current Inspection Today

Don’t wait until a defect causes unplanned downtime. Our eddy current testing services provide fast, reliable, and accurate inspection results for turbines, aerospace, and industrial components.

Using advanced eddy current array systems, we deliver precise corrosion detection, crack detection, and coating evaluation—without the need for disassembly.

Contact us today to schedule your eddy current inspection and learn how we can improve your reliability, safety, and efficiency.