Magnetic Particle Inspection Services

Precision Surface & Subsurface Flaw Detection for Turbines, Welds, and Ferrous Materials

Reliable Magnetic Particle Testing for Critical Components

Magnetic particle inspection (MPI) is a non-destructive testing method (NDT) used to detect surface and subsurface discontinuities in ferromagnetic materials. Using controlled magnetic fields and specialized fluorescent particles, our certified technicians identify flaws, cracks, and defects that compromise component integrity.

At Advanced Turbine Support, our magnetic particle testing services ensure safety, reliability, and quality assurance across turbine components, valves, and welds—without requiring full disassembly.

Comprehensive Particle Inspection Services

Our particle inspection services are designed to locate even the smallest discontinuity or subsurface defect in your ferrous components. Whether using dry powder, fluorescent suspension, or yoke techniques, we adapt our inspection services to each part’s geometry and service environment.

We specialize in:

- Fluorescent Magnetic Particle Testing (FMPI) – Ideal for near-surface and subsurface discontinuities in complex turbine geometries.

- Yoke & Coil Inspections – Portable, precise inspection methods for field work on valves, bolts, and welds.

- Wet & Dry Powder Techniques – Reliable NDT methods to detect surface cracks and leakage paths in steel and alloy parts.

- MPI for Castings & Welds – Identify inclusions, defects, or discontinuities in castings and welds before they become critical.

How Magnetic Particle Inspection Works

Magnetic particle testing operates on the principle of magnetization and leakage flux. When a magnetic field is applied to a ferromagnetic material, any discontinuity such as a crack, inclusion, or void interrupts the flow of magnetic lines. This interruption creates a leakage field, which attracts fluorescent or dry powder particles to the area, clearly marking the flaw’s location.

Because the process is nondestructive, it provides immediate, visual flaw detection results without harming the test material.

Advantages of Magnetic Particle Inspection

Magnetic particle inspection remains one of the most efficient non-destructive testing services for ferrous components due to its speed, precision, and cost-effectiveness.

Key Advantages:

- Detects surface and subsurface discontinuities quickly and accurately

- Works effectively on ferromagnetic materials such as iron, nickel, and cobalt

- Provides clear, visible indications of flaws and defects

- Portable MPI testing equipment suitable for on-site turbine applications

- Complies with ASME, NADCAP, and industry accreditation programs

Our Advanced MPI Testing Process

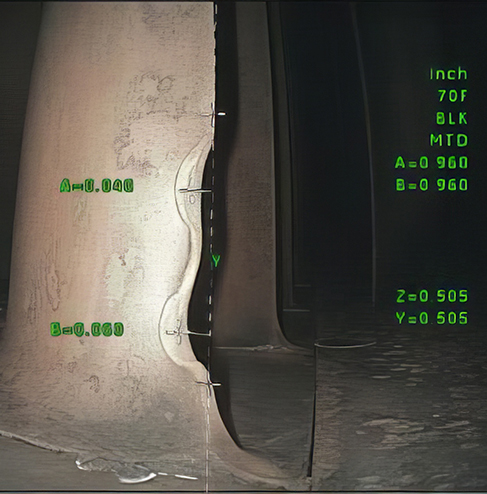

Our MPI testing process begins by establishing a magnetic field around the test surface using coils or a yoke. Fluorescent or dry powder particles are then applied to highlight any subsurface discontinuities or surface defects.

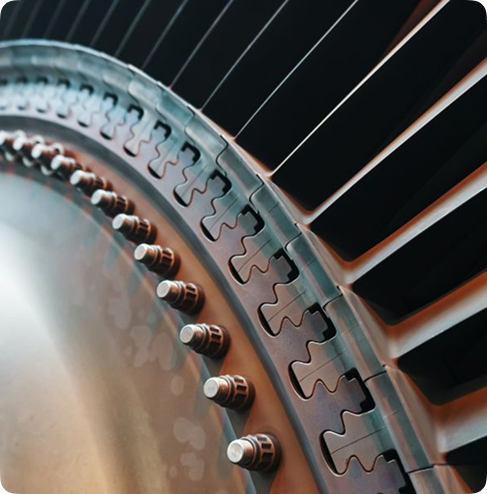

Using advanced magnetization control and fluorescent indication, we can detect cracks in complex geometries—including dovetails, fasteners, castings, and turbine blades. This method ensures reliable inspection results and consistent quality assurance across every job.

NDT Laboratory and Quality Assurance

All testing is performed within our certified NDT laboratory by highly trained inspectors following ASME and NADCAP standards. Every non-destructive testing procedure is validated to meet stringent industry benchmarks for safety and accuracy.

Our inspection services integrate magnetic particle testing, penetrant, and eddy current evaluations to ensure complete component coverage and documentation. This multi-layered NDT method guarantees reliable inspection results, traceability, and compliance.

Why Choose Advanced Turbine Support

Advanced Turbine Support delivers precision, reliability, and safety through certified magnetic particle inspection services—helping operators detect defects early, reduce downtime, and extend equipment life.

Certified MPI Technicians

Experienced professionals trained in ASME and NADCAP standards.

Advanced Detection Equipment

State-of-the-art magnetic particle testing and fluorescent imaging systems.

Comprehensive NDT Solutions

Integration with penetrant, eddy current, and visual inspection methods.

Unmatched Accuracy

Identifies defects, inclusions, and discontinuities with pinpoint precision.

Mag Particle testing

Industries We Serve

Advanced Turbine Support provides magnetic particle testing services for a wide range of critical industries:

Aerospace: Detecting micro-cracks in ferrous engine and landing gear components.

Power Generation: Ensuring turbine and weld integrity through routine inspection.

Petrochemical & Energy: Evaluating castings, valves, and pressure components.

Manufacturing & Fabrication: Verifying flaws in ferromagnetic materials before assembly or shipment.

Certifications

Gallery

Magnetic particle inspections

At Advanced Turbine Support, every inspection is more than a procedure — it’s a promise of performance, safety, and precision. With our proven inspection process, cutting-edge borescope equipment, and dedicated inspectors, you’ll gain the confidence that comes from knowing your systems are in optimal condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule a Magnetic Particle Inspection Today

Ensure your turbines, castings, and welds remain safe, efficient, and fully compliant. Our MPI testing delivers fast, reliable flaw detection for ferrous components using fluorescent and dry powder applications.

Contact Advanced Turbine Support today to schedule your magnetic particle inspection and keep your assets performing at their best.