Liquid Dye Penetrant Inspection services

Detect surface defects with unmatched precision — ensuring turbine components perform safely and reliably.

Why liquid Dye Penetrant Testing Is Essential for Precision Maintenance

Surface cracks and defects invisible to the naked eye can lead to catastrophic failures if ignored. Dye Penetrant Inspection (DPI), also known as liquid penetrant testing (LPI), is a non-destructive testing (NDT) method used to detect surface defects such as cracks, porosity, and leaks in metallic and non-porous materials.

This testing method relies on capillary action—the natural ability of the penetrant to be applied to the surface, seep into surface-breaking defects, and reveal flaws that are otherwise not visible to the naked eye. By identifying these surface-breaking discontinuities early, dye penetrant testing helps extend asset life, improve reliability, and reduce costly downtime for aerospace, power generation, and industrial clients.

Comprehensive liquid Dye Penetrant Inspections for Industrial Applications

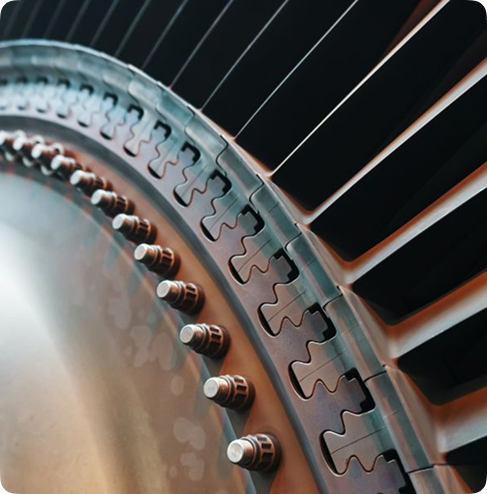

Advanced Turbine Support provides both fluorescent and visible liquid dye penetrant inspection services for gas turbines, steam turbines, compressors, and industrial rotating equipment. Our penetrant inspections detect surface-breaking defects in forgings, ceramics, plastics, and metal components, using ASTM- and ASME-compliant penetrant testing procedures.

Includes:

- Fluorescent (Type I) and visible (Type II) methods

- Water-washable and solvent-removable techniques

- Field and shop-based inspections

- Reporting and digital defect documentation

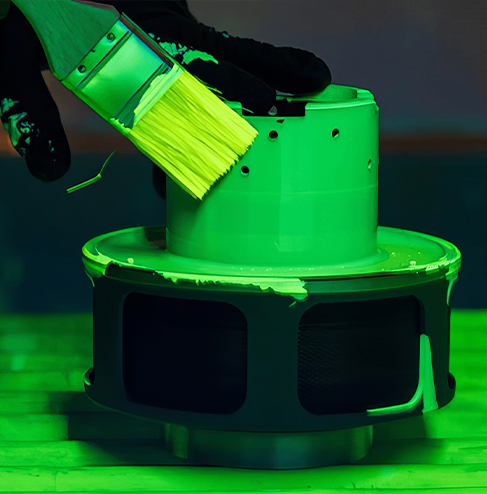

Whether the method used is dipping, spraying, or brushing the penetrant onto the surface, every penetrant is applied and removed in strict accordance with ASTM E1417 standards.

Precision Tools, Proven Processes

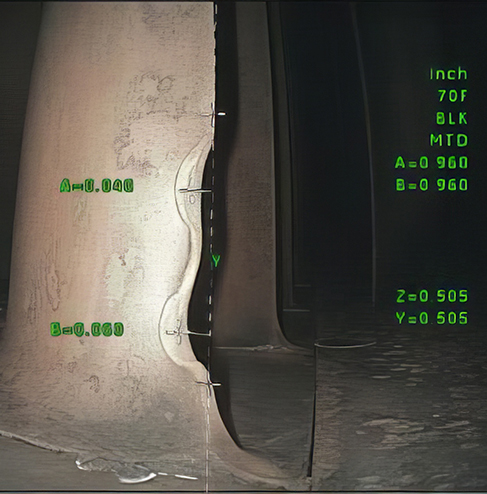

Our liquid penetrant inspection process begins by cleaning the test surface to remove contaminants. Next, the penetrant is applied by spray, dip, or brush, allowing it to enter surface-breaking discontinuities through capillary action. After the appropriate dwell time or penetration time, any excess penetrant from the surface is carefully cleaned—often with a solvent depending on the type of penetrant used.

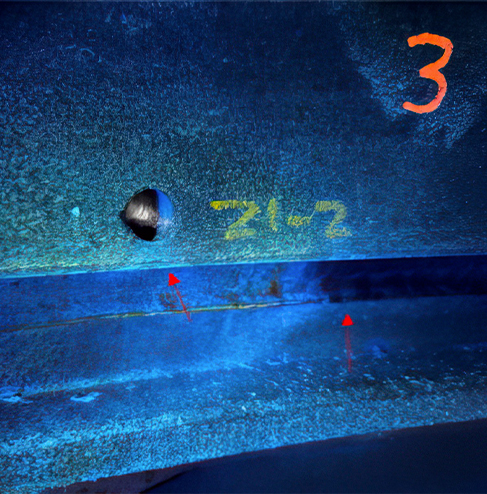

Once the excess penetrant is removed, a developer is applied to the test object. The developer helps draw the penetrant back out of any surface flaws and create a visible indication of the discontinuity. These visible indications, made clear under ultraviolet or white light, reveal even the smallest cracks open to the surface.

All penetrant inspections are performed with precise control of sensitivity levels, dwell time, and developer application to ensure consistent, reliable results.

Fluorescent & Visible liquid Penetrant Testing

Advanced Turbine Support offers both fluorescent and liquid visible dye methods to detect surface-breaking defects across a variety of materials.

- Fluorescent penetrants are examined under ultraviolet light, offering superior sensitivity levels ideal for turbine blades and aerospace components.

- Visible dye penetrant systems are inspected under white light, providing quick and portable inspection capability for on-site testing.

Both types of penetrant used are selected depending on the type of component, lighting, and inspection environment to ensure maximum accuracy.

Certified Technicians & Documentation

Each liquid penetrant inspection is conducted by ASNT-certified Level II and Level III technicians with decades of experience in non-destructive evaluation. Our teams maintain meticulous documentation to record visible indications, testing methods, and procedural compliance.

All inspection data, images, and defect reports are stored digitally, allowing clients to track trends and verify non-destructive testing results over time.

Your Trusted Partner for liquid Dye Penetrant Testing

Our inspection process is built around accuracy, safety, and speed. Here’s what you can expect when you schedule your inspection with Advanced Turbine Support:

25+ Years of NDT Exprerience

Experience performing penetrant testing on all major OEM turbine models and aerospace components.

ASTM & ASME Compliant Methods

Each inspection follows proven industry procedures to detect surface flaws.

Global 24/7 Service Available

From the field to your facility, our specialists inspect with precision and speed.

Actionable Digital Reports

Every penetrant inspection includes digital images, visible indications, and recommendations.

liquid Dye Penetrant inspections

Serving the World’s Most Trusted Power Generation Brands

Our certified inspectors perform dye penetrant inspections on test objects and turbine components for GE, Siemens, Alstom, and Mitsubishi. Power generation, petrochemical, and aerospace companies depend on us for precise non-destructive testing that keeps assets safe and reliable.

Advanced In-Situ Liquid Penetrant Testing Services for Turbine Reliability

Advanced Turbine Support, LLC has developed and implemented several advanced in-situ Liquid Penetrant inspections. With the manpower and capability to perform remote visible dye and fluorescent inspections, Advanced Turbine Support can work with you to ensure you are utilizing the inspections that best meet your needs. These inspections exceed OEM requirements and provide our customers with the information they need to make educated decisions to best manage their generation demands.

Certifications

Gallery

Dye Penetrant testing

At Advanced Turbine Support, every dye penetrant test represents our commitment to uncovering the smallest surface flaws with precision, ensuring your equipment operates safely and reliably under any condition.

World's Best Gas

and Steam Turbine

Inspection Company

Schedule your Liquid dye penetrant inspection today

If your facility relies on turbines, engines, or other industrial systems, you can’t afford to overlook the importance of advanced inspection methods. Preventive evaluations—such as liquid penetrant inspection, visible dye inspection, and fluorescent penetrant testing—are essential components of modern non-destructive testing programs that safeguard performance, efficiency, and long-term reliability.

Whether you require a remote visual inspection of hard-to-reach turbine sections, a detailed pipeline or casing analysis, or precision surface evaluation using dye penetrant techniques, our team has the experience and specialized equipment to deliver accurate, repeatable results in any environment.

Contact Advanced Turbine Support today to schedule your inspection and experience why leading organizations in power generation, aerospace, and heavy industry trust us for non-destructive testing services that exceed OEM standards and deliver actionable data — in real time.