Turbine steam cleaning

High-precision steam turbine cleaning services designed to prepare components for inspection, support hot gas path work, and recover lost efficiency without introducing chemical risk.

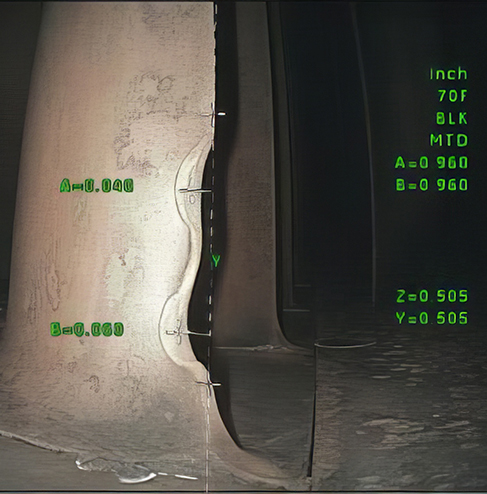

Surface Preparation for High-Level NDE (“White Rag Clean”)

High-level non-destructive examination demands exceptionally clean surfaces. Our steam cleaning process achieves a white-rag-clean condition, ensuring oils, residues, and contaminants are fully removed before inspection begins.

This level of preparation supports:

- Magnetic Particle Inspection (MPI)

- Dye Penetrant Inspection (DPI)

- Visual and dimensional inspections

- Accurate, repeatable NDE results

Pre-Inspection Cleaning Use Case

Steam cleaning is often the first critical step before inspections. By removing deposits that mask cracks, corrosion, and wear, steam cleaning ensures inspection findings reflect true component condition—not contamination.

Pre-inspection steam cleaning helps:

- Prevent missed indications and false positives

- Reduce re-inspection and rework

- Improve confidence in inspection results

- Keep outage schedules on track

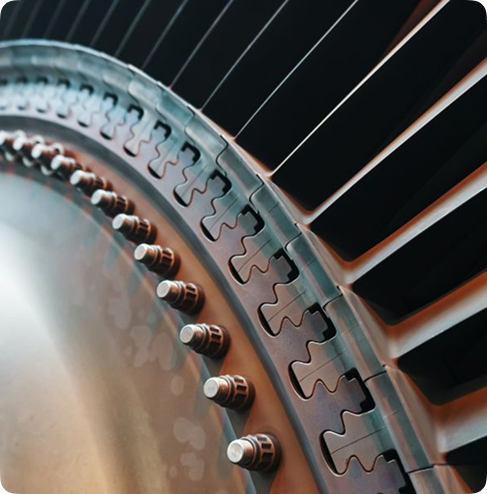

Optional Performance & Aerodynamic Cleaning (MW Gain)

Beyond inspection readiness, steam cleaning can deliver measurable performance benefits. Removing fouling from flow-path surfaces can restore aerodynamic efficiency and reduce pressure losses.

Potential performance benefits include:

- Improved turbine efficiency

- Restored airflow and pressure profiles

- Potential MW output gains

- Improved heat rate performance

Used Under Major Inspections & Hot Gas Path Work

Steam cleaning is commonly performed ahead of major inspections and hot gas path outages. Clean components enable accurate inspections, reliable repair decisions, and smoother execution once work begins.

Common applications include:

- Major turbine inspections

- Hot gas path inspections and repairs

- Component refurbishment planning

- Repair scope validation

Also Available as a Standalone Service

While frequently tied to outages, steam cleaning can be performed as a standalone service. This allows operators to address fouling, performance degradation, or inspection preparation independently of major outage windows.

Standalone use cases include:

- Performance degradation investigations

- Pre-outage preparation

- Mid-cycle cleaning

- Fleet-wide efficiency initiatives

Why turbine steam cleaning matters

Trusted Gas Turbine Inspection Specialists

Expose Hidden Defects

Remove deposits that hide cracks and damage

Improve Inspection Accuracy

Enable reliable NDE and visual inspections

Recover Performance

Reduce fouling-related efficiency losses

Support Better Decisions

Ensure findings are based on real conditions

Steam Cleaning

Steam Cleaning That Improves Outcomes — Not Just Appearance

Steam cleaning is not cosmetic—it is a critical step in preparing turbines for accurate inspections and reliable performance evaluation. Without proper cleaning, deposits and residue can mask cracks, wear, and material degradation, leading to compromised inspection results and incomplete data.

By removing fouling and contamination early, steam cleaning helps eliminate uncertainty before key outage decisions are made. Clean components allow inspection methods to perform as intended, reducing the risk of missed indications, repeat work, or late-stage scope changes.

Whether performed ahead of a major inspection, hot gas path work, or as a standalone service, steam cleaning directly supports better execution and smarter decisions. In many cases, it also delivers measurable performance recovery by restoring aerodynamic efficiency and reducing flow-path losses.

Certifications & Qualifications

Gallery

Engineering support

A closer look at how precision steam cleaning reveals true component condition, supports accurate inspections, and restores turbine performance.

World's Best Gas

and Steam Turbine

Inspection Company

Prepare Your Turbine the Right Way — Before Inspections Begin

If you’re planning a major inspection, hot gas path outage, or addressing performance degradation, now is the time to ensure your turbine is properly cleaned. Our steam cleaning services eliminate uncertainty, improve inspection accuracy, and help protect outage success.