Condition-based risk analysis for steam & Gas Turbines

Balance of Plant / Service duty requirement evaluations

In depth evaluation of unit operating requirements supports lifecycle management/outage planning.

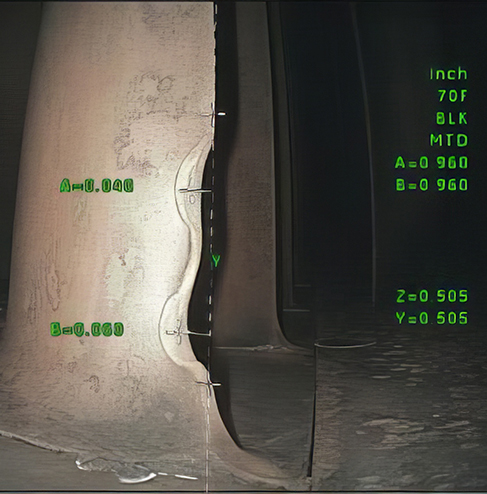

Condition & Inspection Correlation

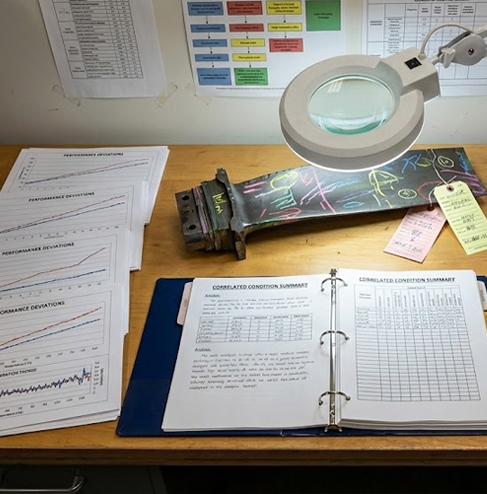

Operational data tells us how the turbine behaves—inspection results tell us why. By aligning measurable performance deviations with NDE/NDT findings, we uncover the root causes of degradation such as creep, oxidation, erosion, or material fatigue. This step converts raw inspection reports into actionable engineering insight.

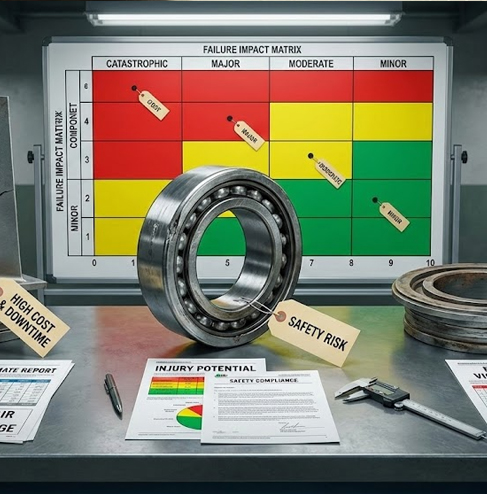

Probability of Failure Assessments

Utilizing the proven Failure Modes Effects Criticality Analysis process our team of turbine engineers provide a statistical evaluation of failure risk. Evaluating the as found conditions, inspection & repair history, balance of plant & service duty requirements.

Failure Analysis Output

Our reports provide our customers the ability to make data driven lifecycle management decisions. Detailed recommendation to manage the assessed risks.

Risk Management Strategy

With failure probability and consequence defined, we build a strategy that determines what to repair now, what to monitor, and what can be safely deferred to a future outage. This ensures planning decisions are condition-based, minimizing unnecessary teardown while protecting uptime, budget, and lifecycle value.

Advantages of condition-based analysis

Why Advanced Turbine Support Can Help

Protect Your Outage Schedule

Identify critical path components before the outage begins.

Reduce Capital Spending

Replace only what needs replacing—based on measurable condition.

Extend Component Life

Push overhaul intervals safely without compromising asset integrity.

Prevent Forced Outages

Stop failures before they occur by detecting root causes early.

Condition-based risk analysis

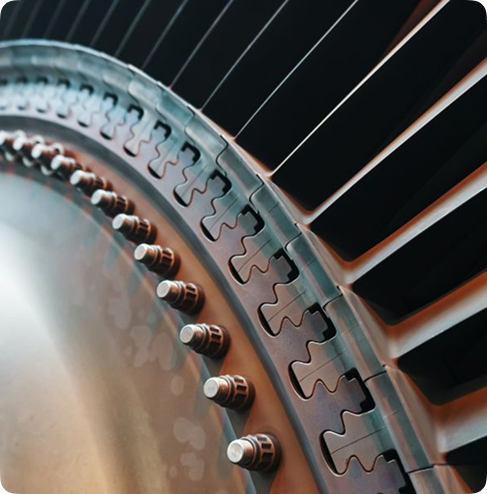

COMPREHENSIVE CONDITION-BASED RISK ANALYSIS SERVICES

Our risk analysis framework combines operational data, engineering evaluation, and failure-mode assessment to determine which turbine components require immediate attention—and which can safely remain in service.

We evaluate:

- Historical operating trends (load cycles, start/stop counts, thermal gradients)

- Inspection history and current component conditions

- Maintenance History (outage intervals & repairs)

- NDE/NDT findings (UT, FPI, EC, hardness mapping, runout)

- Fuel and steam purity effects (corrosion, stress cracking, pitting)

- Service duty requirement history & forecast

- Balance of plant operations

The result is a prioritized, risk-ranked action plan that supports safer inspection intervals, more predictable outage durations, and controlled maintenance spending.

Certifications

Gallery

CBRE

At Advanced Turbine Support, every dye penetrant test represents our commitment to uncovering the smallest surface flaws with precision, ensuring your equipment operates safely and reliably under any condition.

World's Best Gas

and Steam Turbine

Inspection Company

schedule a condition-based risk analysis today

Protect your turbine from hidden failure risks and take control of outage planning. Our specialists will review your operational history and provide a detailed assessment of where intervention is required—and where it isn’t.