COMPREHENSIVE STEAM TURBINE MAJOR OUTAGE PLANNING

Minimize downtime, optimize performance, and ensure safety with our turnkey outage management and technical planning services.

PRE-OUTAGE SCOPE DEFINITION & ASSESSMENT

A successful outage begins long before the turbine shuts down. We assist in defining the precise scope of work 18–24 months in advance. Our team reviews historical operational data, previous outage execution reports, and current generator performance metrics to identify critical path activities.

RESOURCE & LOGISTICS MANAGEMENT

Managing the supply chain is critical to preventing schedule slippage. We handle the logistical heavy lifting to ensure your site is ready day one.

- Procurement of long-lead time capital parts.

- Coordination of specialized tooling and heavy lifting equipment.

- Sourcing and vetting of specialized labor forces.

CRITICAL PATH SCHEDULING

SAFETY PLANNING & COMPLIANCE

Safety is the backbone of our planning process. We develop comprehensive EHS (Environmental, Health, and Safety) plans tailored to your facility’s specific hazards.

- Site-specific LOTO (Lock Out / Tag Out) procedure development.

- Confined space entry management and rescue planning.

- Foreign Material Exclusion (FME) zone establishment.

CONTINGENCY & EMERGENT WORK STRATEGY

"Found work" is inevitable during major overhauls of gas turbines. Our best practice planning includes robust contingency protocols to address unexpected findings—such as erosion, cracking, or alignment issues—without derailing the entire schedule with longer outage durations. We provide rapid engineering dispositions to keep the project moving.

WHY CHOOSE ADVANCED TURBINE SUPPORT FOR OUTAGE PLANNING?

Your Partner in Safe, Efficient Turbine Outage Planning

ON-TIME EXECUTION

Our rigorous scheduling ensures you return to grid synchronization on or ahead of the planned date.

SAFETY FIRST

We maintain an industry-leading safety record with zero lost-time incidents on managed outages.

OEM EXPERTISE

Decades of experience working across GE, Siemens, Westinghouse, and Mitsubishi platforms.

COST CONTROL

Transparent budget management that minimizes variance and eliminates hidden costs.

Quaternary Annulus Chamber

Restoring Peak Reliability With Expert Steam Turbine Major Outage Planning

Your steam turbine’s performance depends on precise coordination—and even small missteps in planning can cascade into extended downtime, unexpected costs, and compromised asset reliability. A major outage is where operational risk is highest, and without a disciplined, data-driven plan, delays, scope creep, and schedule overruns become inevitable.

At Advanced Turbine Support, our Major Outage Planning Turbine Services integrate historical operating data, OEM specifications, and field-proven methodologies to engineer a complete outage roadmap. We define exact work scope, align resources, schedule inspections, and anticipate contingencies—ensuring every task is controlled, validated, and executed with precision.

Whether preparing for a first-time major overhaul or optimizing your long-term maintenance cycle, our process protects your investment against costly errors, unplanned component replacements, and operational disruption—delivering safer execution, reduced outage times, and improved turbine availability across your entire power-generation cycle.

Certifications

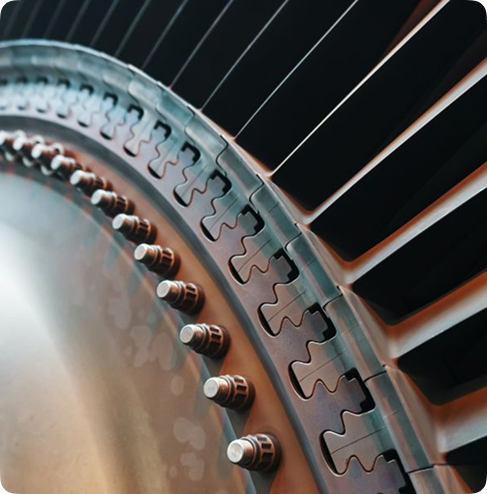

Gallery

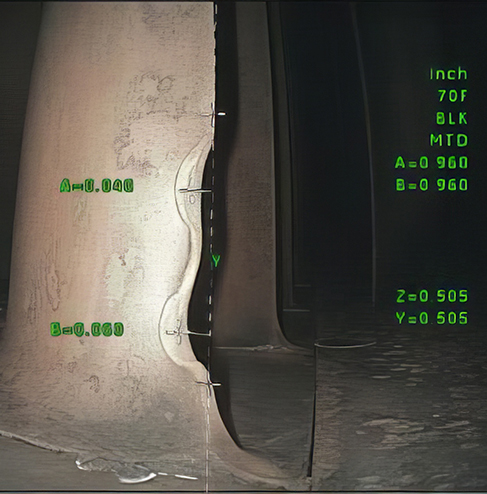

Quaternary Annulus Cleaning

At Advanced Turbine Support, every dye penetrant test represents our commitment to uncovering the smallest surface flaws with precision, ensuring your equipment operates safely and reliably under any condition.

World's Best Gas

and Steam Turbine

Inspection Company

START PLANNING YOUR NEXT OUTAGE TODAY

Don’t wait until the last minute. Secure your power plant resources and optimize your schedule now.